In the world of internal combustion engines, the intake valve plays a critical role in ensuring optimal performance, efficiency, and emissions. Whether you're driving a car, riding a motorcycle, or operating heavy machinery, the intake valve is an essential component that directly impacts how your engine runs. This blog will explore the function, types, and importance of intake valves in modern engines, as well as their evolution and future trends.

What is an Intake Valve?

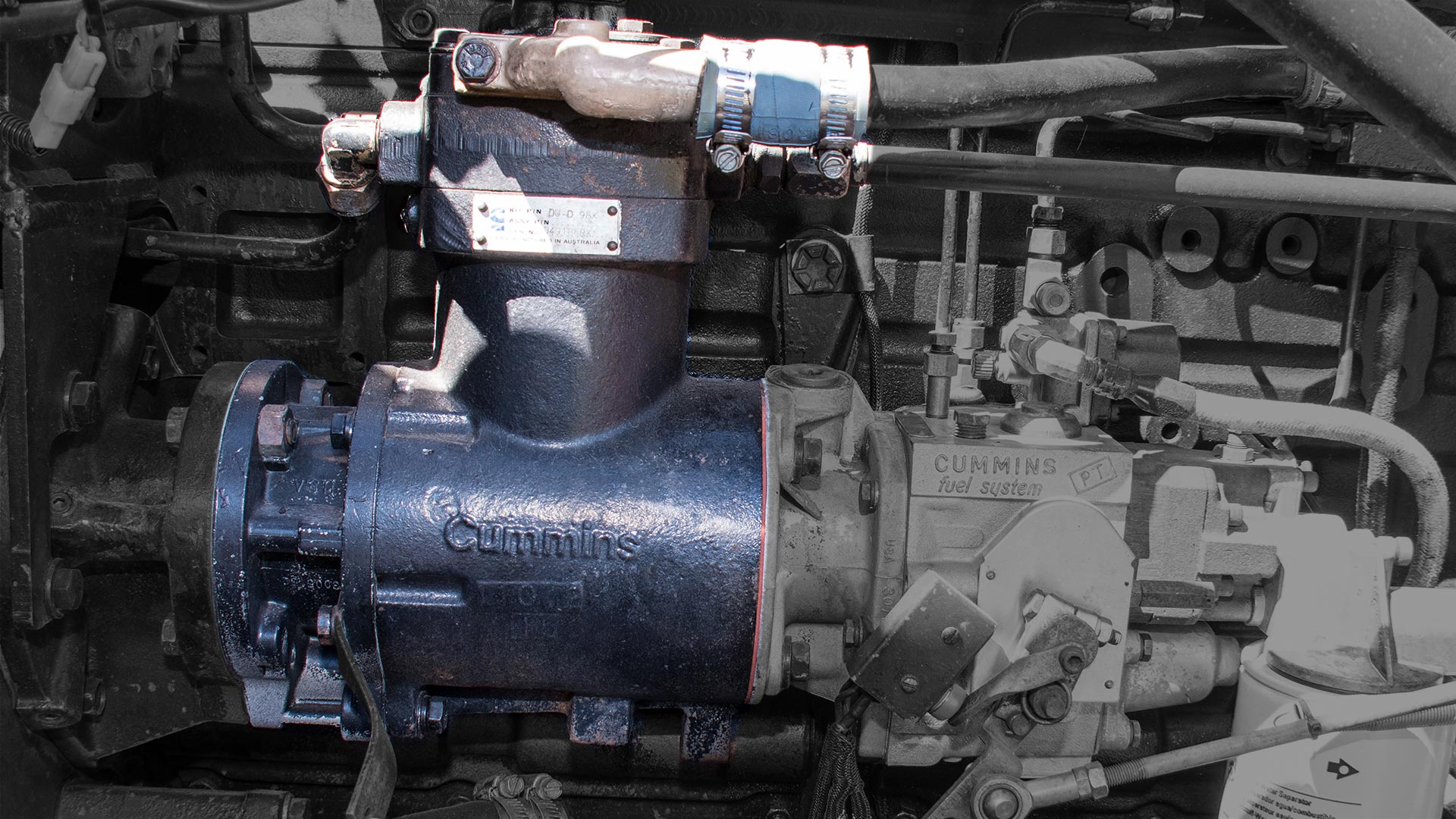

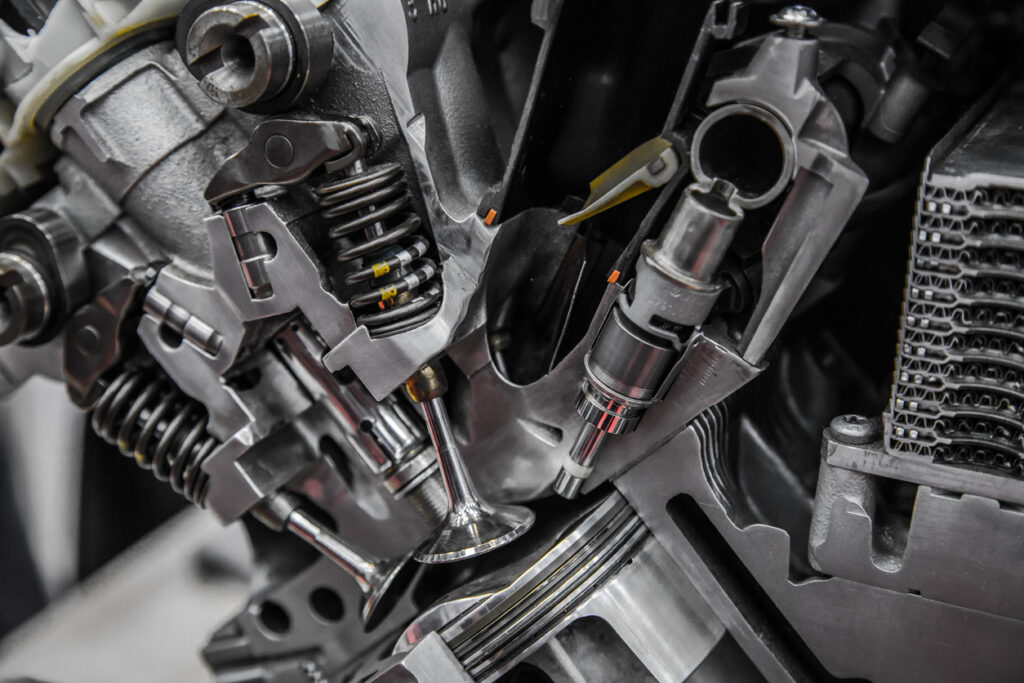

An intake valve is a mechanical component in an internal combustion engine that controls the flow of air (or air-fuel mixture) into the combustion chamber. Its primary function is to open and close in synchronization with the engine's operation, allowing fresh air into the cylinder during the intake stroke and sealing it during the compression and combustion strokes. This precise timing is crucial for maximizing power output, improving fuel efficiency, and reducing emissions.Intake valves are typically located in the engine's cylinder head and work in conjunction with exhaust valves. Together, they form the valve train system, which is managed by the engine's camshaft, timing belt, and other related components.

The Function of Intake Valves

1.Air Flow Regulation: The intake valve ensures that the right amount of air enters the combustion chamber at the correct time. This is vital for maintaining the air-fuel ratio, which directly affects engine performance and efficiency.

2.Timing and Synchronization: Intake valves open and close in perfect timing with the engine's pistons. This synchronization is achieved through the camshaft, which follows the engine's timing sequence. Modern engines often use electronic systems, such as Variable Valve Timing (VVT), to adjust intake valve timing based on driving conditions.

3.Efficiency and Power: By controlling the airflow, intake valves help the engine achieve better combustion. This leads to increased power output and reduced fuel consumption. Advanced intake valve designs, such as those with variable lift or timing, further enhance engine efficiency.

4.Emissions Control: Proper intake valve function ensures that the air-fuel mixture burns completely, reducing harmful emissions like carbon monoxide (CO) and hydrocarbons (HC).

Types of Intake Valves

1.Standard Intake Valves: These are the most common type of intake valves used in engines. They operate on a fixed timing and lift, meaning their opening and closing times, as well as the distance they open, are predetermined by the engine design.

2.Variable Intake Valves (VVT): Variable intake valves are designed to adapt to different engine speeds and load conditions. By adjusting the timing and lift of the intake valve, these systems optimize airflow and combustion efficiency. This technology is widely used in modern cars to improve fuel economy and reduce emissions.

3.Rotary Intake Valves: Unlike traditional poppet valves, rotary intake valves use a rotating mechanism to control airflow. This design is often found in high-performance engines, such as those in racing cars, due to its ability to handle higher airflow rates and faster switching speeds.

Importance of Intake Valve Maintenance

Intake valves are subjected to extreme conditions inside the engine, including high temperatures, pressure, and mechanical stress. Over time, they can wear out or become damaged, leading to reduced engine performance or even failure. Regular maintenance is essential to ensure that intake valves function properly.

1.Valve Clearance Checks: Over time, intake valves can develop excessive clearance due to thermal expansion. Regular checks and adjustments are necessary to maintain optimal performance.

2.Carbon Buildup: Deposits of carbon can accumulate on intake valves, especially in engines with high mileage. Cleaning or replacing the valves can restore proper airflow and combustion.

3.Valve Spring Replacement: The springs that control the intake valve's movement can lose tension over time, leading to poor valve sealing or timing issues. Replacing worn-out springs is a critical part of engine maintenance.

4.Lubrication: Proper lubrication of the valve train system ensures smooth operation and reduces wear and tear on the intake valves.

Future Trends in Intake Valve Technology

As engines become more sophisticated, intake valve technology is evolving to meet the demands of higher efficiency, reduced emissions, and improved performance. Some emerging trends include:

1.Electronically Controlled Valves: Instead of relying on mechanical camshafts, electronically controlled valves use solenoids or other electronic actuators to manage the opening and closing of intake valves. This allows for precise control and adaptability to various driving conditions.

2.Lightweight Materials: The use of lightweight materials, such as advanced composites or aluminum alloys, is becoming more common to reduce the overall weight of the engine and improve fuel efficiency.

3.Hybrid Valve Systems: Combining traditional poppet valves with rotary or electronically controlled valves could offer a balance of performance, efficiency, and reliability in future engines.

4.Intelligent Valve Control: With the integration of AI and machine learning, intake valves could be optimized in real-time based on engine load, speed, and environmental conditions. This would further enhance engine performance and reduce emissions.

Conclusion

Intake valves are the unsung heroes of internal combustion engines, working tirelessly behind the scenes to ensure smooth operation and optimal performance. From regulating airflow to controlling emissions, their role is indispensable. As technology advances, we can expect intake valves to become even more efficient and intelligent, paving the way for cleaner, more powerful engines in the future.