The Yanmar shutoff solenoid is a crucial component in the operation of a Yanmar engine, playing a vital role in controlling fuel flow. Understanding its function, maintenance methods, and troubleshooting techniques helps ensure your equipment operates reliably. In this blog, we'll delve into the details of the Yanmar shutoff solenoid, explaining its importance and providing practical advice to ensure proper engine operation.

What is the Yanmar Shutoff Solenoid?

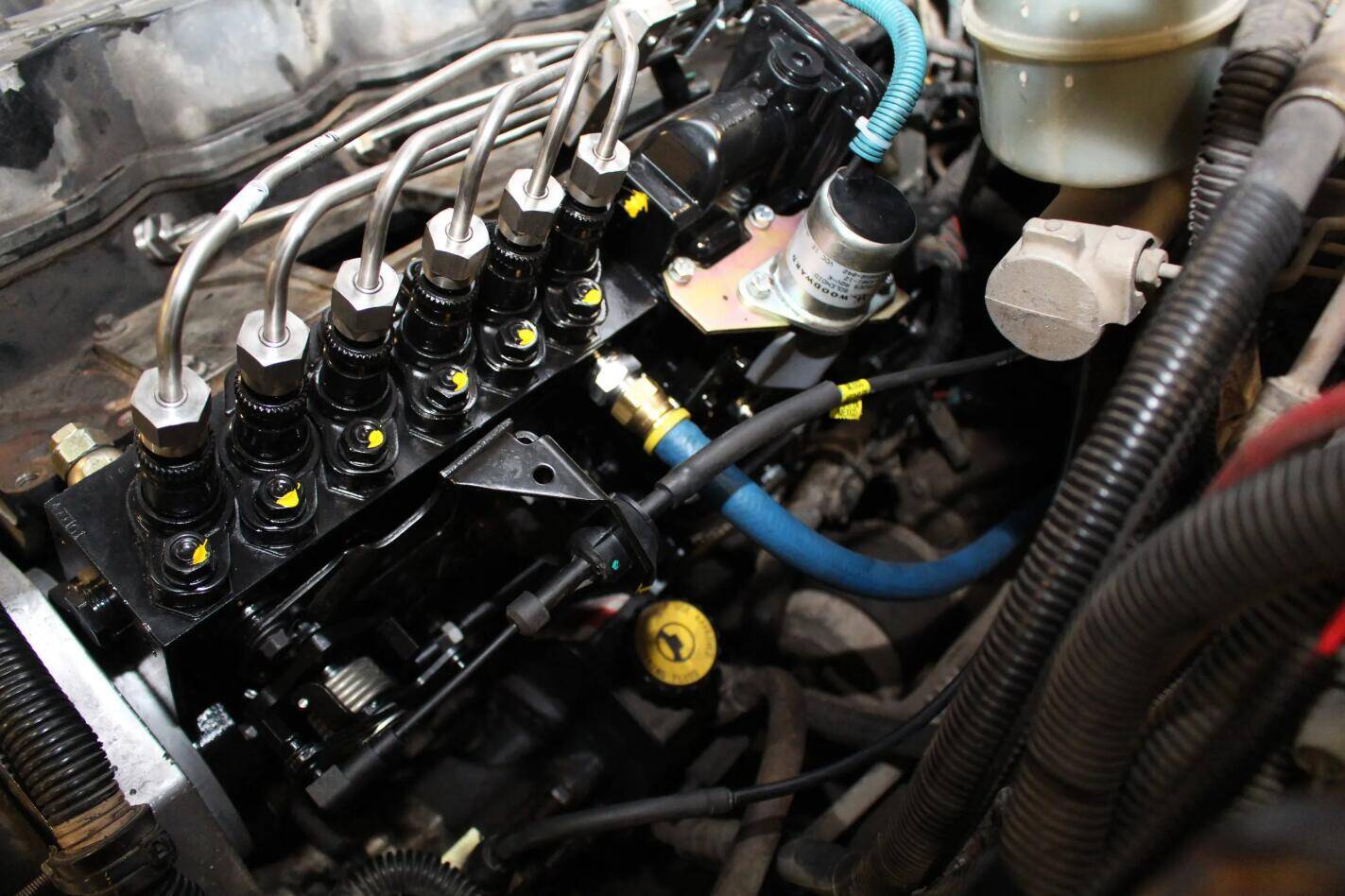

This shut-off solenoid is a type of electromagnetic valve used to control fuel flow in Yanmar engines. Its main function is to open or close the fuel line based on an electrical signal to ensure the engine receives the correct amount of fuel for optimal performance. When the engine starts or stops, this solenoid valve acts as a switch, making it an indispensable part of the fuel delivery system. In Yanmar engines, shut-off solenoid valves are typically used in conjunction with other components such as fuel injectors or fuel pumps to regulate fuel supply. They are commonly found in diesel and gasoline engines where precise fuel control is crucial for efficiency and engine lifespan.

Why is the Shutoff Solenoid Important?

1.Engine Protection:

This solenoid prevents fuel from flowing to the engine when the engine is not running, which helps protect the engine from unnecessary wear.

2.Fuel Efficiency::

By ensuring accurate fuel flow, this solenoid helps improve fuel efficiency and reduce operating costs.

3.Reliability:

A well-functioning shutoff solenoid ensures smooth engine start-up and shutdown, thereby minimizing the risk of unexpected shutdowns or starting difficulties.

Given its importance, regular maintenance of Yanmar shutoff solenoid and timely troubleshooting are crucial to avoiding costly repairs and equipment downtime.

Common Issues with the Yanmar Shutoff Solenoid

Despite its reliability, the shutoff solenoid can experience problems over time. Here are some common issues to watch out for:

1.Malfunctioning Solenoid Coil:

The solenoid coil may be damaged due to overheating, wear, or electrical faults. If the coil fails, the solenoid will not be able to open or close properly, resulting in problems with fuel delivery.

2.Leakage or Blockage:

Dust, debris, or wear can cause leaks or blockages in the solenoid valve. This can lead to poor fuel flow, thus affecting engine performance.

3.Sticking or Jamming:

If the solenoid becomes stuck in the open or closed position, it can cause the engine to either run continuously or fail to start.

4.Electrical Faults:

Loose connections, damaged wires, or voltage fluctuations can disrupt the solenoid’s operation, leading to inconsistent fuel flow.

Maintenance Tips for the Yanmar Shutoff Solenoid

To keep your Yanmar shutoff solenoid in top condition, follow these maintenance tips:

1.Regular Inspections:

Inspect the solenoid for signs of wear, corrosion, or physical damage. Also check for loose connections or cracked housings.

2.Cleanliness is Key:

Ensure that the solenoid and its surrounding components are free of dust and debris. A clean environment reduces the risk of contamination and malfunction.

3.Test the Solenoid:

Regularly test the solenoid to ensure it is functioning correctly. You can do this by manually activating it or by using diagnostic tools to monitor its electrical performance.

4.Replace Worn Parts:

If the solenoid coil, O-ring, or other components show signs of wear, they should be replaced immediately. Using high-quality replacement parts is crucial for maintaining performance.

5.Follow Manufacturer Guidelines:

Troubleshooting the Yanmar Shutoff Solenoid

1.Check the Electrical Connection:

Check the wiring and connections for looseness or damage. Ensure the solenoid receives the same voltage as specified in the manual.

2.Test the Solenoid for Response:

Use a multimeter to test the resistance and continuity of the solenoid. If the solenoid valve does not respond to an electrical signal, it may need to be replaced.

3.Inspect for Physical Damage:

Inspect the solenoid housing for any obvious signs of wear or cracks. If damage is found, replace the solenoid immediately to avoid further problems.

4.Clean or Replace Clogged Components:

If the solenoid is dirty or clogged, it should be carefully cleaned or the affected part replaced. This usually resolves fuel flow-related issues.

5.Monitor Engine Performance:

Pay attention to phenomena such as difficulty starting, unstable idling, or unexpected shutdown. These symptoms may indicate a malfunction in the shutoff solenoid.

Preventive Measures for Longevity

Preventing issues with the Yanmar shutoff solenoid is easier than fixing them. Here are some preventive measures to keep in mind:

1.Use High-Quality Fuel:

Contaminated fuel can damage solenoid and other engine components. Always use clean, high-quality fuel as recommended by Yanmar.

2.Regular Oil Changes:

Dirty oil can damage internal engine components, including solenoid. Please strictly follow the recommended oil change schedule.

3.Avoid Overheating:

Overheating can impair the performance of the solenoid coil. Ensure the cooling system is functioning properly and monitor engine temperature during operation.

4.Store the Engine Properly:

If your Yanmar engine is idle for extended periods, store it in a clean, dry environment to prevent rust or damage to the solenoid.

5.Keep the Engine Well-Lubricated:

Proper lubrication reduces friction and wear, ensuring the solenoid operates smoothly over time.

Why Choose Yanmar?

Yanmar engines are renowned for their durability, reliability, and advanced technology. This shutoff solenoid is just one example of the meticulous engineering incorporated into every Yanmar product. With a focus on innovation and sustainability, Yanmar consistently maintains its leading position in the industry. For users who rely on Yanmar engines for agricultural, construction, or power generation needs, understanding this shutoff solenoid is crucial for maintaining optimal performance and avoiding costly downtime.

Conclusion

The Yanmar shutoff solenoid is a small but indispensable part of your engine’s fuel system. By understanding its role, performing regular maintenance, and addressing issues promptly, you can ensure the solenoid operates effectively and extends the lifespan of your engine. Remember, prevention is key—so stay proactive and keep your Yanmar equipment running like new.