Transmission valves are critical components in the operation of automatic transmissions, playing a pivotal role in ensuring smooth gear shifts, optimal performance, and efficient fluid flow within the transmission system. In this blog post, we will explore the importance of transmission valves, their types, and how they contribute to the overall functionality of a vehicle.

What Are Transmission Valves?

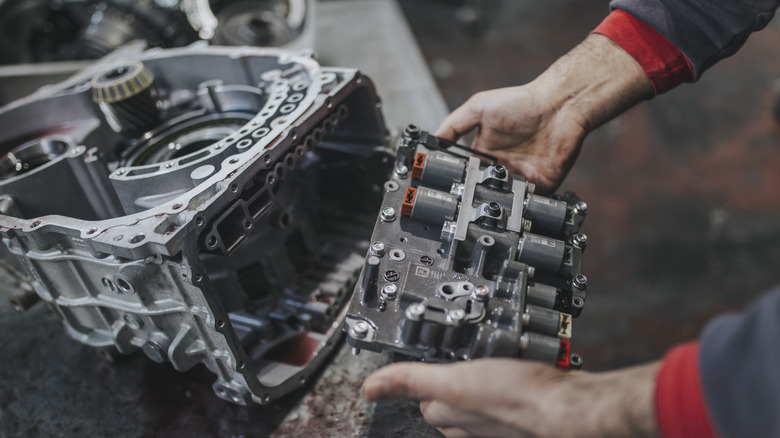

Transmission valves are small, precision-engineered components that regulate the flow of transmission fluid within the automatic transmission system. They are responsible for directing hydraulic pressure to the appropriate clutch or band at the right time, ensuring that the transmission shifts gears smoothly and efficiently. These valves are typically located within the transmission control module or the valve body, and they work in conjunction with sensors, solenoids, and other hydraulic components to manage the shifting process.

Types of Transmission Valves

1.Manual Shift Valve (MSV):

The MSV is a critical component in most automatic transmissions. It is responsible for controlling the flow of hydraulic fluid to the clutches and bands, which in turn determines the gear engagement. The MSV ensures that the transmission shifts gears at the correct time based on input from the vehicle's computer system.

2.Throttle Valve (TV):

The Throttle Valve is a mechanical valve that responds to the accelerator pedal position. It regulates the amount of hydraulic pressure applied to the transmission components, ensuring that the transmission shifts gears in accordance with the driver's input and the vehicle's speed.

3.Pressure Control Valve (PCV):

The PCV is responsible for maintaining the appropriate hydraulic pressure within the transmission system. It ensures that the transmission fluid is at the correct pressure level to engage and disengage the clutches and bands effectively.

4.Solenoid Valve:

Solenoid valves are electronically controlled valves that respond to signals from the transmission control module (TCM). They are used in more advanced transmission systems, such as those with electronic controls, to regulate the flow of hydraulic fluid to specific components.

How Transmission Valves Function

Transmission valves operate within a hydraulic system that uses transmission fluid to create pressure. When the engine is running, the transmission pump generates hydraulic pressure, which is then regulated by the valves. The valves direct this pressure to the appropriate clutches and bands, which engage or disengage to shift gears.For example, during a gear shift, the MSV will open or close to allow fluid to flow to the necessary clutch or band. This ensures that the transmission engages the correct gear ratio, providing the driver with smooth and seamless gear transitions. If a transmission valve becomes worn or malfunctioning, it can lead to improper gear engagement, resulting in rough shifts or even transmission failure.

Signs of Transmission Valve Wear

Transmission valves are subject to wear and tear over time due to the constant flow of fluid and pressure changes. Some common signs of transmission valve wear include:

Rough Gear Shifts: If the transmission valves are not functioning properly, gear shifts may become rough or jerky.

Fluid Leaks: Worn or damaged valves can cause fluid leaks, which may lead to low transmission fluid levels.

Slipping Gears: In some cases, worn valves may cause the transmission to slip between gears, resulting in a loss of power and acceleration.

Check Engine Light: Malfunctioning transmission valves can trigger the Check Engine Light, as the vehicle's computer detects irregularities in the transmission system.

Maintaining Transmission Valves

Regular maintenance of the transmission system is essential to ensure the proper functioning of transmission valves. This includes:

Checking Transmission Fluid: Regularly inspecting and replacing transmission fluid can help prevent wear and tear on the valves.

Monitoring Symptoms: Pay attention to signs of transmission issues, such as rough shifts or fluid leaks, and address them promptly.

Professional Repairs: If transmission valves are damaged or worn, it is advisable to seek professional repairs or replacements to avoid further damage to the transmission system.

The Future of Transmission Valves

As automotive technology continues to evolve, transmission valves are becoming more sophisticated. Modern transmissions often incorporate electronic controls and advanced valve designs to improve shifting accuracy and efficiency. Additionally, the use of high-quality materials and improved manufacturing processes is leading to longer-lasting and more reliable transmission valves.In conclusion, transmission valves are integral to the smooth operation of automatic transmissions. Understanding their role, recognizing signs of wear, and maintaining them properly can help ensure optimal performance and longevity of your vehicle's transmission system. Always remember to consult a professional if you suspect any issues with your transmission valves, as timely repairs can prevent costly damage and keep your vehicle running smoothly.