Hydraulic systems are the backbone of many industrial, agricultural, and automotive applications, providing the necessary power and precision for tasks that require heavy-duty operations. At the heart of these systems lies a variety of components, one of which is the hydraulic pump proportional solenoid valve. This blog will explore the functionality, benefits, and applications of this critical component, shedding light on its role in modern hydraulic systems.

What is a Hydraulic Pump Proportional Solenoid Valve?

A proportional solenoid valve is a type of control valve that regulates the flow of hydraulic fluid in a system. Unlike traditional on/off solenoid valves, which only allow full flow or no flow, proportional solenoid valves provide precise control over the flow rate by adjusting the valve opening proportionally to the input signal. This makes them ideal for applications that require fine-tuned control, such as speed regulation, pressure adjustment, and load handling.In the context of a hydraulic pump, the proportional solenoid valve is often used to control the displacement or flow rate of the pump. By adjusting the valve, operators can manage the pump's output to match the specific requirements of the system, ensuring efficiency and performance.

How Does It Work?

The operation of a hydraulic pump proportional solenoid valve is based on the principles of electromagnetic induction and fluid dynamics. Here’s a simplified breakdown:

1.Electromagnetic Actuation: The valve contains a solenoid coil that generates a magnetic field when an electrical current is applied. This magnetic field moves a plunger or spool, which in turn controls the opening of the valve.

2.Proportional Control: The degree of valve opening is directly proportional to the strength of the input signal. For example, a 50% signal will result in a 50% opening, allowing partial fluid flow. This proportional control enables precise adjustments in pressure, flow rate, and system response.

3.Integration with the Hydraulic Pump: In a hydraulic pump system, the proportional solenoid valve is often connected to the pump’s control mechanism. By regulating the fluid flow into or out of the pump, it can control the pump's displacement, which determines the volume of fluid it can move per cycle.

4.Feedback Mechanisms: Advanced proportional solenoid valves may incorporate feedback mechanisms, such as position sensors, to ensure accurate and consistent control. These sensors provide real-time data on the valve's position, allowing for fine adjustments and maintaining system stability.

Key Benefits of Hydraulic Pump Proportional Solenoid Valves

1.Precision Control: The ability to adjust the valve opening proportionally ensures that the hydraulic pump operates at optimal levels, delivering the exact amount of fluid required for a task.

2.Improved Efficiency: By regulating the pump's displacement, proportional solenoid valves help reduce energy consumption and minimize fluid waste, making the system more efficient.

3.Fast Response Time: Hydraulic systems often require rapid adjustments to meet changing demands. Proportional solenoid valves offer quick response times, ensuring smooth and reliable operation.

4.Reduced Maintenance: Compared to mechanical control systems, proportional solenoid valves are less prone to wear and tear, reducing the need for frequent maintenance and extending the system's lifespan.

5.Versatility: These valves can be integrated into a wide range of hydraulic systems, from small-scale machinery to large industrial equipment, making them a versatile solution for various applications.

Applications of Hydraulic Pump Proportional Solenoid Valves

Proportional solenoid valves are widely used in industries where precise control of hydraulic systems is essential. Some common applications include:

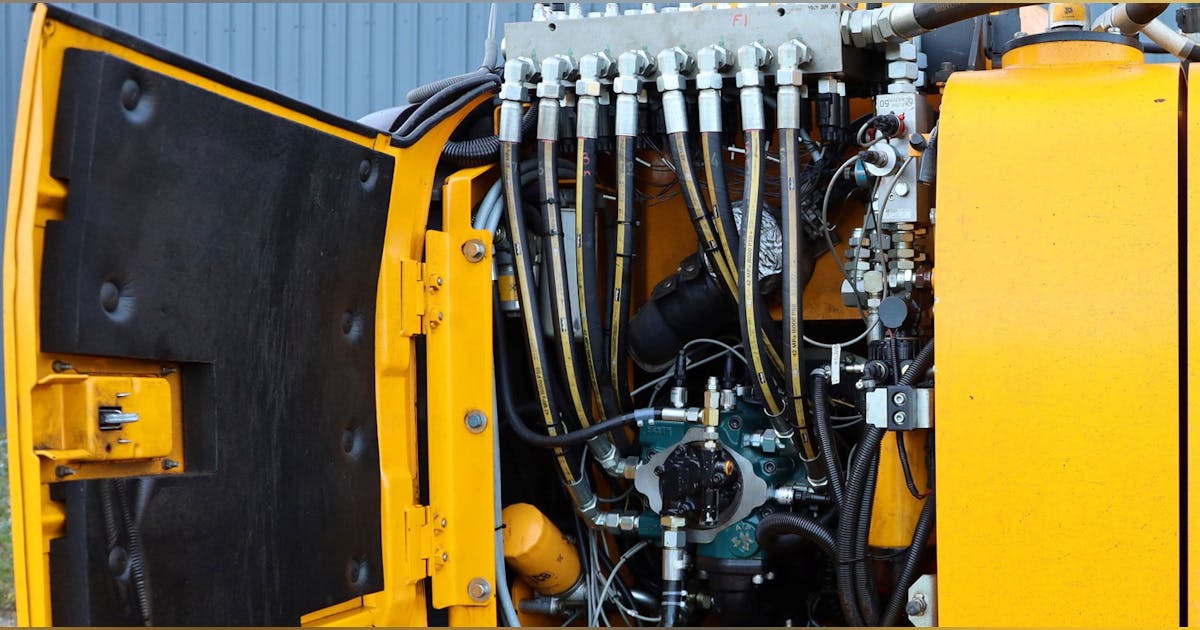

1.Construction Machinery: In excavators, bulldozers, and other heavy machinery, proportional solenoid valves regulate the flow of hydraulic fluid to control the speed and force of actuators.

2.Agricultural Equipment: Tractors, harvesters, and other farming machinery rely on these valves to manage hydraulic functions such as lifting, tilting, and steering.

3.Automotive Industry: In vehicle braking systems, power steering, and automatic transmissions, proportional solenoid valves ensure smooth and responsive operation.

4.Industrial Automation: Proportional solenoid valves are used in automated production lines to control hydraulic cylinders and motors, enabling precise movements and operations.

5.Renewable Energy: In wind turbines and hydroelectric systems, these valves play a crucial role in regulating hydraulic pressure and flow for efficient energy generation.

Challenges and Considerations

While hydraulic pump proportional solenoid valves offer numerous advantages, there are some challenges and considerations to keep in mind:

1.Signal Accuracy: The performance of the valve depends heavily on the accuracy of the input signal. Any fluctuations or inaccuracies in the electrical current can affect the valve's operation.

2.Environmental Factors: Exposure to extreme temperatures, humidity, or contaminants can impact the longevity and reliability of the valve. Proper installation and maintenance are essential.

3.Power Consumption: The electromagnetic coil in the valve requires a continuous power supply. In energy-sensitive applications, this can be a consideration.

4.Compatibility: Ensuring that the proportional solenoid valve is compatible with the hydraulic pump and the overall system is critical for optimal performance.

Choosing the Right Valve for Your Hydraulic Pump

Selecting the appropriate proportional solenoid valve for your hydraulic pump involves several factors:

1.System Requirements: Understand the specific needs of your hydraulic system, including flow rate, pressure, and response time.

2.Valve Type: There are different types of proportional solenoid valves, such as linear and proportional pressure valves. Choose the one that best fits your application.

3.Quality and Reliability: Invest in high-quality valves from reputable manufacturers to ensure durability and consistent performance.

4.Control Signals: Determine whether your system uses analog or digital control signals, as this will influence the choice of valve.

5.Installation and Maintenance: Consider the ease of installation and ongoing maintenance requirements to avoid disruptions in your operations.

Conclusion

Hydraulic pump proportional solenoid valves are indispensable components in modern hydraulic systems, offering precise control, improved efficiency, and versatile applications. As technology continues to advance, these valves are becoming more sophisticated, with features like digital control and advanced feedback mechanisms enhancing their performance.